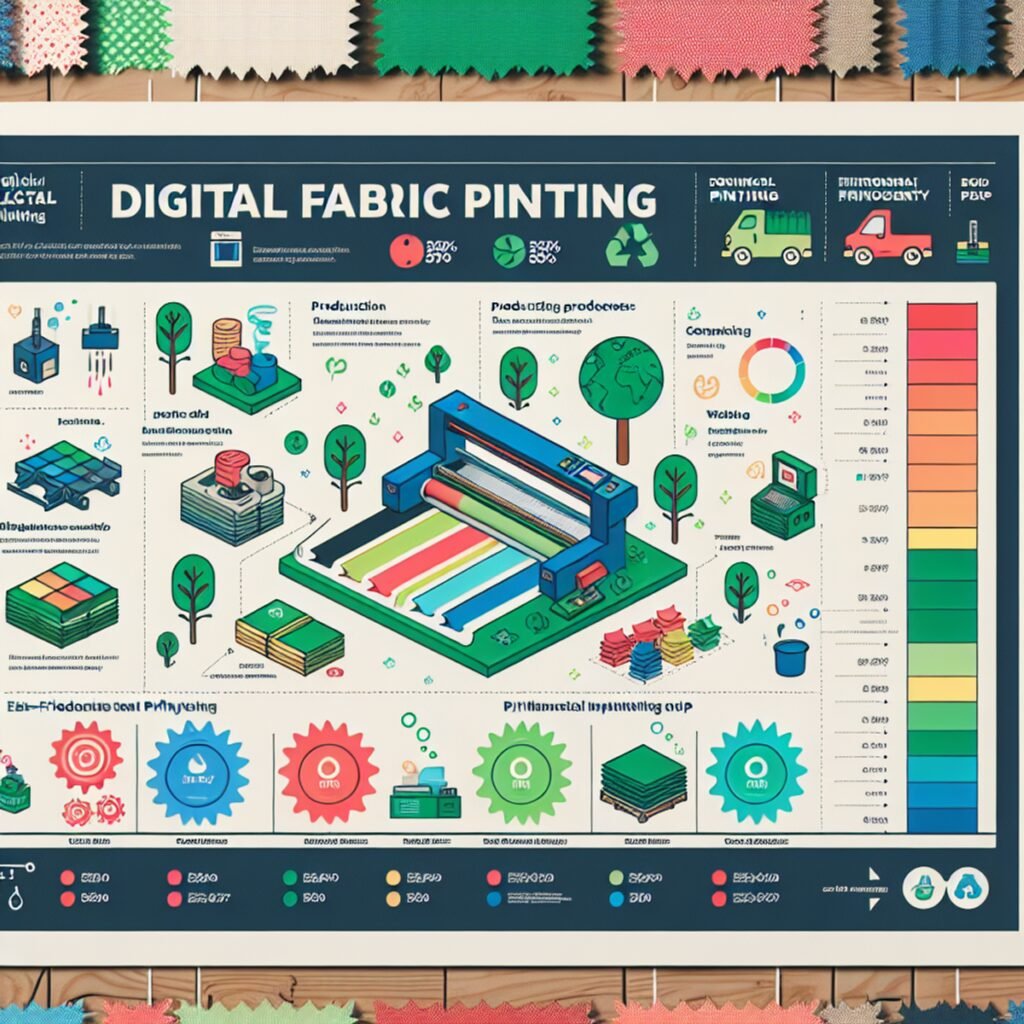

Introduction to Digital Fabric Printing Eco-Friendly

Digital fabric printing has emerged as a game-changer in the textile industry, offering a more sustainable approach to fabric production. In this article, we will explore the eco-friendliness of digital fabric printing and its role in promoting sustainability in the textile industry.

What is Digital Fabric Printing?

Digital fabric printing involves using digital technology to directly apply ink onto fabrics, without the need for traditional printing methods like screen printing or rotary printing. This technique offers advantages such as:

- Greater design flexibility

- Customization options

- Reduced material waste

- Increased efficiency

Our Approach

By exploring key areas such as environmental impact, eco-friendly features, materials, and technological advancements, we aim to provide a comprehensive understanding of the topic.

Throughout this discussion, we will:

- Examine the environmental impact of traditional fabric printing methods and compare them to digital printing techniques.

- Highlight key eco-friendly features in digital fabric printing processes, such as waterless processes, safer chemicals, and eco-friendly ink formulations.

- Explore the role of sustainable materials in advancing ecological integrity within the industry.

By embracing both technological advancements and sustainable practices, we can pave the way for a more environmentally friendly future in fabric printing. Join us as we uncover the potential of digital fabric printing to contribute to a greener and more sustainable textile industry.

Understanding the Environmental Impact of Traditional Fabric Printing Methods

Traditional fabric printing methods have been widely used in the textile industry for many years. These methods involve various techniques, such as screen printing, block printing, and rotary printing. While these methods have their merits in terms of versatility and cost-effectiveness, they also come with significant negative environmental consequences.

One of the key environmental concerns associated with traditional fabric printing is the use and discharge of harmful chemicals into ecosystems. These chemicals include dyes, pigments, binders, and other additives that are necessary for achieving vibrant and long-lasting prints. Unfortunately, many of these chemicals are toxic and non-biodegradable, posing a threat to both human health and the environment.

The use of these chemicals in traditional fabric printing processes leads to water pollution when they are discharged into rivers and other water bodies. The untreated wastewater from printing factories often contains high levels of pollutants, such as heavy metals and organic compounds, which can have detrimental effects on aquatic life and ecosystems. Additionally, the energy-intensive nature of traditional printing methods contributes to carbon emissions and further exacerbates climate change.

In summary:

- Traditional fabric printing methods utilize a range of techniques such as screen printing, block printing, and rotary printing.

- These methods involve the use of harmful chemicals that are toxic and non-biodegradable.

- The discharge of these chemicals into ecosystems leads to water pollution and poses a threat to aquatic life.

- The energy-intensive nature of traditional printing methods contributes to carbon emissions.

By understanding the environmental impact of traditional fabric printing methods, we can better appreciate the need for eco-friendly alternatives like digital fabric printing. In the following sections, we will explore the advantages of digital fabric printing in terms of sustainability and its potential to revolutionize the textile industry.

Examining the Eco-Friendly Advantages of Digital Fabric Printing

Digital fabric printing is a modern technique that offers several eco-friendly advantages, aligning with the sustainability goals of the textile industry. This method involves using digital files to print designs directly onto fabric, eliminating the need for traditional printing screens and plates.

1. Water and Energy Efficiency

The eco-friendly nature of digital fabric printing stems from its water and energy efficiency. Unlike traditional methods that require substantial amounts of water for washing and rinsing processes, digital printing significantly reduces water consumption. Additionally, it minimizes energy usage by directly applying inks to the fabric, bypassing lengthy preparation steps involved in conventional printing.

2. Design Flexibility

Another key advantage lies in the design flexibility offered by digital printing techniques. With digital printing, intricate and detailed designs can be easily achieved without extensive setup or material waste. This flexibility allows for on-demand production, reducing excess inventory and material usage.

Digital fabric printing not only minimizes environmental impact but also enhances operational efficiency and resource utilization. Its eco-friendly features make it a compelling choice for sustainable fabric production in today’s textile industry.

Key Eco-Friendly Features in Digital Fabric Printing Processes

Digital fabric printing offers several key eco-friendly features that set it apart from traditional methods. These features contribute to the sustainability and environmental benefits of this modern printing technique. Here are the main points to consider:

- Waterless Processes: One of the significant advantages of digital fabric printing is its minimal water consumption. Unlike traditional methods that require large quantities of water for dyeing and washing, digital printing uses waterless processes. This not only conserves water resources but also reduces the pollution caused by the discharge of wastewater into ecosystems.

- Safer Chemicals: Traditional fabric printing methods often involve the use of harmful chemicals, such as azo dyes and formaldehyde-based resins. These chemicals pose a risk to both human health and the environment. In contrast, digital printing utilizes safer chemical alternatives that are free from toxic substances. This contributes to a healthier working environment for textile workers and minimizes the impact on ecosystems.

- Eco-Friendly Ink Formulations: Digital fabric printing employs water-based inks that are eco-friendly and non-toxic. These inks have a lower environmental impact compared to solvent-based inks used in traditional methods. Additionally, advancements in inkjet technology have led to the development of earth-friendly pigment inks derived from renewable sources like soy or vegetable oils.

- Reducing Carbon Footprint: Digital printing can help reduce the carbon footprint of the textile industry through on-demand production and minimal resource consumption. With digital technology, fabrics can be printed directly from digital files without the need for intermediate steps like screen preparation or color mixing. This eliminates waste associated with excess inventory and reduces energy consumption during production.

- Waste Reduction: Digital fabric printing offers potential waste reduction benefits throughout the production process. In pre-production stages, digital printing allows for precise color matching, reducing the need for multiple sample runs and minimizing fabric waste. Furthermore, digital printing enables customization and on-demand production, reducing the risk of overproduction and resulting in less textile waste. Additionally, the materials used in digital printing, such as water-based inks and recyclable fabric substrates, can be recycled or repurposed, further reducing waste.

Digital fabric printing’s eco-friendly features make it a sustainable choice for the textile industry. It minimizes water consumption, uses safer chemicals and eco-friendly ink formulations, reduces the carbon footprint through on-demand production and waste reduction practices, and promotes recyclable materials. By embracing these key features, the textile industry can move towards a more sustainable future.

Promoting Sustainability Through Materials in Digital Fabric Printing

In addition to the technological advancements and eco-friendly practices within digital fabric printing, it is important to consider the role of sustainable materials in promoting sustainability in the textile industry. By using sustainable fabrics and other environmentally friendly materials, we can further enhance the eco-friendliness of digital printing processes.

Broadening the Scope of Eco-Friendliness

While digital printing offers significant advantages in terms of reducing water consumption, energy usage, and waste generation, it is essential to take a holistic approach to fabric printing sustainability. By considering sustainable fabric printing methods alongside technology-driven solutions like digital printing, we can achieve a more comprehensive and environmentally friendly approach.

Sustainable Fabrics and Ecological Integrity

Sustainable fabrics play a crucial role in advancing ecological integrity within the textile industry. These fabrics are made from fibers that are grown and produced using environmentally friendly practices. For example:

- Organic cotton: Cotton grown without the use of synthetic pesticides or fertilizers.

- Hemp: A highly sustainable fiber that requires minimal water and no pesticides.

- Bamboo: A fast-growing plant that requires minimal water and has natural anti-bacterial properties.

By incorporating these sustainable fabrics into digital printing processes, we can ensure that the entire production cycle aligns with principles of environmental responsibility.

Environmentally Friendly Materials for Digital Printing

In addition to sustainable fabrics, there are other environmentally friendly materials that are compatible with digital printing processes. These include:

- Water-based inks: Unlike traditional printing methods that use solvent-based inks, digital fabric printing utilizes water-based inks that are non-toxic and have lower VOC emissions.

- Recyclable materials: Digital printing often involves recyclable materials such as polyester fabrics made from recycled plastic bottles. These materials can be reused or repurposed after their lifecycle, contributing to a circular economy.

By selecting these materials for digital fabric printing, we can further reduce the environmental impact of the printing process and promote sustainability in the textile industry. Incorporating sustainable fashion design principles into this approach would create a more ethical and environmentally responsible industry overall.

A Holistic Comparison: Environmental Impact and Other Considerations

When comparing the environmental impact of digital fabric printing to traditional methods, it’s important to consider various factors beyond just eco-friendliness. Here’s a balanced assessment:

1. Environmental Impact

Digital fabric printing significantly reduces the use and discharge of harmful chemicals into ecosystems compared to traditional methods. This makes it a more environmentally friendly option, aligning with sustainability goals.

2. Durability of Prints

Traditional fabric printing methods often result in more durable prints, particularly when considering wear and tear over time. Digital prints may not always match this level of durability, which is an important aspect to consider when evaluating environmental impact.

3. Cost-Effectiveness

While digital fabric printing offers eco-friendly advantages, it may be less cost-effective than traditional methods due to initial setup costs and material expenses. It’s essential to weigh these costs against the long-term sustainability benefits.

Considering these factors holistically, digital fabric printing emerges as a more environmentally friendly option, despite potential drawbacks in terms of print durability and cost-effectiveness. It aligns with sustainable practices by minimizing chemical usage and resource consumption, contributing positively to the textile industry’s ecological integrity.

The Role of Technology: Dye Sublimation and Inkjet Innovations in Digital Fabric Printing

Digital fabric printing relies on advanced technologies to bring designs to life. Two key methods that have revolutionized the industry are dye sublimation and inkjet printing.

Dye Sublimation

- Dye sublimation is a process where heat is used to transfer dye onto materials such as plastic, paper, or fabric.

- In the context of fabric printing, this method involves transferring dye from a solid directly to a gas without transitioning through a liquid state.

- The gas then permeates the fabric’s fibers and solidifies into the material, resulting in vibrant, long-lasting prints.

- Dye sublimation is particularly popular for producing sportswear, flags, banners, and other products requiring durable, high-quality prints. If you’re looking for a beginner’s guide on dye sublimation, this article on sublimation for beginners provides valuable insights.

Inkjet Technology

- Inkjet printing, on the other hand, involves propelling droplets of ink onto the fabric to create designs.

- This method offers versatility in color application and can accommodate intricate patterns with precision.

- It has become a preferred choice for small-scale production runs and customized designs due to its ability to handle complex images and fine details. If you’re interested in understanding how inkjet printers work in detail, this comprehensive guide on inkjet printers provides valuable insights.

- Inkjet technology also allows for efficient ink usage and minimal waste, making it an eco-friendly option within digital fabric printing.

These technologies have significantly contributed to the eco-friendliness of digital fabric printing by reducing resource consumption, minimizing waste, and offering high-quality results. As digital fabric printing continues to evolve, advancements in dye sublimation and inkjet technologies are expected to further enhance sustainability practices within the textile industry.

Future Forward: Embracing Sustainability in the Digital Era of Fabric Printing

The textile industry is at a critical point where it must adopt both technology and sustainable practices to ensure the future of eco-friendly fabric printing. The rise of sustainable fashion movements has led to an increased demand for greener production methods, such as digital printing. This shift towards sustainability reflects the growing environmental consciousness among consumers and the industry’s dedication to reducing its carbon footprint.

The Need for Collaboration and Innovation

Achieving comprehensive sustainability in fabric printing processes requires ongoing innovation and collaboration throughout the textile supply chain. Every step, from sourcing raw materials to printing and distribution, must be optimized for eco-friendliness. By incorporating sustainable practices at each stage, the industry can minimize its environmental impact while meeting the rising call for responsibly manufactured textiles.

Exploring New Possibilities with Technology

As technology continues to advance, there is a significant opportunity to further improve the eco-friendliness of digital fabric printing. Developments in ink formulations, printing techniques, and material sourcing are paving the way for even more sustainable methods. By staying updated on these advancements, the industry can continue pushing boundaries and establishing higher benchmarks for environmentally friendly fabric printing.

Embracing Sustainability as a Necessity

In this era of rapid change and heightened environmental awareness, embracing sustainability in fabric printing is no longer a mere option – it is an absolute necessity. It requires a joint effort from all parties involved – manufacturers, designers, and consumers – to forge a more sustainable future for fabric printing. Looking ahead, it is evident that sustainability will remain a guiding force in shaping the digital era of fabric printing.

Conclusion

Digital fabric printing offers several benefits over traditional printing methods, making it a more sustainable choice for the fashion industry:

- Reduced water and energy consumption: Digital printing requires less water and energy compared to conventional methods, helping to conserve these valuable resources.

- Elimination of harmful chemicals: Unlike traditional printing techniques that use toxic dyes and chemicals, digital printing uses water-based inks that are free from harmful substances.

- Less waste production: With digital printing, there is minimal fabric wastage as designs can be printed directly onto the fabric with precision.

By embracing eco-friendly options like digital printing, we can make a positive impact on the environment and work towards a more sustainable future for fabric printing.

To promote sustainability in the fashion industry, individuals can also take practical steps such as:

- Choosing certified eco-friendly products

- Advocating for responsible manufacturing practices

Together, these actions can help create a more conscious and environmentally-friendly approach to fashion.

FAQs (Frequently Asked Questions)

What are the significant negative environmental impacts of traditional fabric printing methods?

The significant negative environmental impacts of traditional fabric printing methods include the use and discharge of harmful chemicals into ecosystems.

What are some eco-friendly advantages of digital fabric printing?

Eco-friendly advantages of digital fabric printing include water and energy efficiency, as well as design flexibility that leads to reduced material waste.

What are some key eco-friendly features in digital fabric printing processes?

Key eco-friendly features in digital fabric printing processes include waterless processes, safer chemicals, eco-friendly ink, reducing carbon footprint, waste reduction, and the use of recyclable materials.

What is the role of sustainable fabrics in promoting sustainability through materials in digital fabric printing?

Sustainable fabrics play a crucial role in advancing ecological integrity within the industry by offering environmentally friendly materials that are compatible with digital printing processes.

How does the environmental impact of digital fabric printing compare to traditional methods in terms of durability and cost-effectiveness?

A holistic comparison takes into account factors such as durability of prints and overall cost-effectiveness when assessing the environmental impact of digital fabric printing compared to traditional methods.

1 thought on “Is Digital Fabric Printing Eco-Friendly? Find Out Now”