Introduction What is Lyocell Fabric is it Sustainable

Lyocell fabric is a popular choice among conscious consumers and designers in the fashion industry due to its sustainable and eco-friendly nature. This fabric is made from natural raw materials, primarily wood pulp from eucalyptus trees. It is known for its durability, flexibility, and versatility, offering various advantages for both consumers and the environment.

In this article, we will explore the production process, environmental impact, benefits, uses, and future prospects of lyocell fabric. By examining these aspects, we aim to provide a comprehensive understanding of why lyocell has become a preferred option for those seeking sustainable fashion alternatives.

Let’s dive into the world of lyocell fabric and see how it has become synonymous with conscious consumption and responsible design.

Understanding Lyocell Fabric

Lyocell Fabric Production: A Sustainable Approach

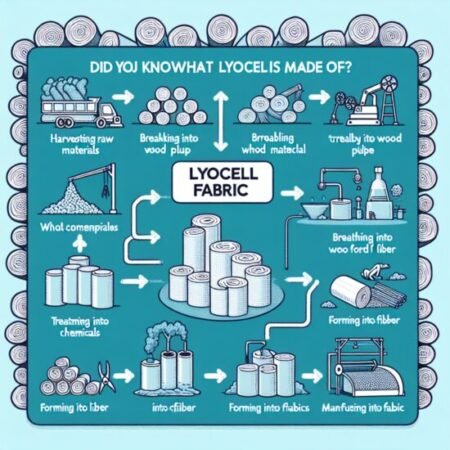

Lyocell fabric is a sustainable and eco-friendly material that has gained recognition in the fashion industry for its innovative production process. This process positions lyocell as a frontrunner in sustainability, with a notable focus on utilizing a closed-loop system to minimize waste and resource consumption. By adopting this approach, the production of lyocell fabric significantly reduces its environmental impact compared to traditional manufacturing methods.

Eco-Friendly Production Process

The key to the sustainable nature of lyocell fabric lies in the use of eco-friendly solvents and low-toxicity chemicals throughout the production process. Unlike other types of rayon fabric such as viscose, which may involve harsh chemicals and have a higher environmental footprint, lyocell’s production process prioritizes the use of gentle solvents and minimizes chemical inputs. This emphasis on environmentally conscious practices ensures that the overall impact of lyocell production is significantly reduced, making it an appealing choice for those seeking sustainable materials.

Closed-Loop System

The utilization of a closed-loop system is a defining feature of lyocell fabric production. This system enables the recycling and reuse of solvents and chemicals, minimizing waste generation and resource consumption. As a result, it contributes to the overall sustainability of the fabric, aligning with the growing demand for environmentally responsible products in the fashion and textile industries.

In summary, the production process of lyocell fabric adopts an innovative and sustainable approach that sets it apart from conventional methods. Through the implementation of a closed-loop system and the use of eco-friendly solvents and low-toxicity chemicals, lyocell fabric showcases a commitment to minimizing its environmental impact while offering high-quality, versatile material for various applications.

The Environmental Impact of Lyocell Fabric

What is Lyocell Fabric?

Lyocell fabric is a type of fabric made from natural cellulose fibers, primarily sourced from wood pulp, especially eucalyptus trees. It is different from traditional fabrics like rayon and viscose because of how it’s made and its unique qualities.

How Lyocell Fabric Benefits the Environment:

Lyocell fabric has several positive environmental effects:

- Promoting Sustainable Forestry: By using raw materials from responsibly managed forests, lyocell fabric supports sustainable forestry practices. Eucalyptus trees, which are often used to make lyocell, grow quickly and don’t require much water or pesticides. This article explains how eucalyptus fabric specifically contributes to sustainable practices.

- Reducing Monoculture Risks: Monoculture plantations can harm the environment by depleting soil nutrients and disrupting local ecosystems. However, growing eucalyptus trees specifically for lyocell production helps decrease these risks associated with monoculture. Organizations such as Canopy Planet are actively working on next-generation solutions for sustainable fabric production.

Challenges and Opportunities for Improvement:

While lyocell fabric offers environmental benefits, there are still areas where it can be improved:

- Resource Consumption: The closed-loop system used in lyocell production minimizes waste and resource usage. However, there may be ways to further optimize resource efficiency. This study on resource optimization in fabric production can provide insights.

- Chemical Usage: Eco-friendly solvents and low-toxicity chemicals are used in the manufacturing process of lyocell fabric. But ongoing research should focus on reducing or replacing certain chemicals to make the fabric even more environmentally friendly.

By assessing the environmental sustainability of lyocell fabric, we acknowledge its positive impact on sustainable forestry and identify potential areas for improvement as the industry continues to prioritize eco-friendly practices.

Advantages and Versatility of Lyocell Fabric

Lyocell fabric offers a range of advantages and versatile properties that make it a preferred choice for both fashion and home applications. Let’s explore some of the key benefits of this sustainable fabric:

1. Superior Comfort

One of the standout features of lyocell fabric is its exceptional comfort. The smooth and soft texture of lyocell makes it incredibly pleasant to wear against the skin. It has a luxurious drape and feels gentle and lightweight, providing a comfortable experience throughout the day.

2. Durability

Despite its softness, lyocell fabric is remarkably durable. The long, fine fibers used in its production contribute to its strength, making it resistant to wear and tear. This durability ensures that garments made from lyocell can withstand regular use and retain their quality for an extended period.

3. Moisture-Wicking

Another advantage of lyocell fabric is its excellent moisture-wicking ability. It has superior absorbency compared to other fabrics such as cotton, which allows it to quickly draw moisture away from the body, keeping you dry and comfortable even in humid conditions.

4. Breathable Nature

Lyocell fabric is highly breathable, allowing air to circulate through the fabric and regulate body temperature effectively. This breathability makes it an ideal choice for activewear, summer clothing, and bedding where comfort and temperature control are essential.

The combination of these properties – comfort, durability, moisture-wicking, and breathability – sets lyocell fabric apart from many other materials in terms of performance and versatility. Whether it’s for everyday clothing, sportswear, or bedding, lyocell fabric offers a unique blend of comfort and functionality that enhances the overall wearing experience.

Lyocell Fabric in the Context of Sustainable Fashion

Lyocell fabric has gained significant recognition in the fashion industry as a sustainable and eco-friendly material. In this section, we will explore the importance of third-party certifications, the role of leading brands like TENCEL™, and initiatives to promote responsible sourcing.

Importance of Third-Party Certifications

One key aspect of ensuring the organic integrity of lyocell fabric is through third-party certifications such as the Global Organic Textile Standard (GOTS). GOTS certification guarantees that the entire production process, from harvesting the raw materials to manufacturing and labeling, meets strict environmental and social criteria. When lyocell fabric is derived from sustainable sources like eucalyptus trees, GOTS certification further reinforces its credibility as a sustainable choice.

Introduction to TENCEL™

TENCEL™ is a leading brand of lyocell fibers developed by Lenzing AG. They have a strong commitment to sustainability throughout their supply chain. TENCEL™ lyocell fibers are made from sustainably sourced wood pulp, primarily from eucalyptus trees. These trees are known for their fast growth and ability to thrive on marginal lands without irrigation or pesticides.

Lenzing AG’s commitment to sustainability goes beyond sourcing raw materials responsibly. They have implemented innovative closed-loop production processes that reduce waste and water consumption. The solvents used in their manufacturing process are also recycled, ensuring minimal environmental impact compared to other manufacturing methods.

Promoting Responsible Sourcing: Certifications and Initiatives

In addition to third-party certifications like GOTS, organizations like Canopy play a crucial role in driving sustainable practices within the lyocell industry. Canopy is an NGO that works with businesses to ensure responsible sourcing of forest-based products. They collaborate with brands and suppliers to develop sourcing policies that prioritize the protection of ancient and endangered forests.

Forestry certifications such as the Programme for the Endorsement of Forest Certification (PEFC) and the Forest Stewardship Council (FSC) are also important in ensuring sustainable sourcing practices. These certifications provide assurance that the wood pulp used in lyocell production comes from responsibly managed forests.

Furthermore, various initiatives and efforts are underway to ensure responsible sourcing of raw materials for lyocell production. For example, Lenzing AG has partnered with Canopy to implement their CanopyStyle initiative, which aims to eliminate sourcing from ancient and endangered forests by 2020. This initiative encourages brands and designers to commit to sustainable sourcing policies and support the demand for responsibly produced fibers.

By supporting brands like TENCEL™ and initiatives like CanopyStyle, consumers can make a positive impact on the fashion industry by choosing lyocell fabric derived from sustainable sources. This not only promotes responsible sourcing practices but also encourages the shift towards a more eco-friendly and socially responsible fashion industry as a whole.

Applications of Lyocell Fabric Across Different Industries

Lyocell fabric has gained popularity not only in the fashion industry but also in various other sectors due to its versatile properties. From clothing to home textiles, the applications of lyocell fabric are diverse and continue to expand. Here are some examples of how this sustainable fabric is being used across different industries:

1. Clothing

Lyocell fabric is a preferred choice for clothing manufacturers and designers due to its exceptional comfort and breathability. It has a silky smooth texture and drapes beautifully, making it suitable for creating luxurious garments. Many fashion brands incorporate lyocell fabric into their collections, offering consumers sustainable alternatives to traditional fabrics. Whether it’s dresses, blouses, or activewear, lyocell provides a soft and lightweight option that feels great against the skin.

2. Home Textiles

Lyocell fabric is also widely used in home furnishings such as bed linens, towels, and upholstery. Its moisture-wicking properties make it an excellent choice for bedding as it helps regulate body temperature and keeps sleepers cool and dry throughout the night. Additionally, its natural antibacterial effect makes it an ideal material for towels that require high levels of hygiene.

3. Fashion Accessories

Beyond clothing and home textiles, lyocell fabric is utilized in fashion accessories like scarves, hats, and bags. The versatility of this fabric allows designers to create unique and stylish accessories that are also eco-friendly.

Renowned brands and designers have recognized the potential of lyocell fabric and have incorporated it into their products. For example:

- Stella McCartney: This luxury brand has been at the forefront of sustainable fashion initiatives and frequently uses lyocell fabric in their collections.

- Eileen Fisher: Another brand known for its commitment to sustainability, Eileen Fisher incorporates lyocell into their clothing line to offer customers comfortable and eco-conscious options.

- Patagonia: This outdoor clothing company utilizes lyocell fabric in their activewear to provide customers with durable and sustainable performance gear.

By leveraging the unique properties of lyocell fabric, these brands are not only creating innovative products but also contributing to a more sustainable and eco-friendly future.

Lyocell’s versatility and eco-friendly characteristics make it a preferred choice for conscious consumers and designers alike. Its applications span across industries, offering comfortable and sustainable alternatives to traditional fabrics. From clothing to home textiles, lyocell fabric continues to make a positive impact in various sectors.

The Future Potential and Challenges Ahead

Recycling Methods for Post-Consumer Waste

Exploration of emerging technologies or innovations that could further enhance the sustainability profile of lyocell fabric includes recycling methods for post-consumer waste. By developing efficient recycling techniques, the fashion industry can reduce its reliance on virgin resources and minimize waste. One such innovation is the mechanical recycling process, which involves shredding used lyocell garments into fibers, then spinning them into new fabrics. This method not only reduces the environmental impact of textile waste but also preserves the valuable properties of lyocell fabric.

Nanotechnology in Lyocell Production

Another promising development is the utilization of nanotechnology in lyocell production. Researchers are exploring ways to incorporate nanoparticles into lyocell fibers to enhance their functional properties. For instance, adding silver nanoparticles can give lyocell antimicrobial properties, making it ideal for medical applications such as wound dressings.

Challenges to Widespread Adoption

However, despite these exciting innovations, there are still some barriers to the widespread adoption of lyocell fabric:

- Scaling up production: One challenge lies in scaling up production to meet increasing demand while maintaining sustainable practices.

- Sustainable sourcing: As lyocell gains popularity, ensuring a consistent supply of sustainably sourced raw materials becomes crucial. Collaboration between lyocell manufacturers and forestry certification organizations like PEFC and FSC is essential in promoting responsible sourcing and preventing deforestation.

- Cost: Additionally, the higher cost of lyocell compared to conventional fabrics poses a barrier for some consumers.

The Role of Brands and Consumers

However, as more brands recognize the importance of sustainability and invest in eco-friendly alternatives, economies of scale may drive down the price of lyocell fabric and make it more accessible to a wider audience.

“The industry’s focus on innovation and sustainability will continue to drive advancements in production methods and address barriers to adoption. By embracing these changes and supporting brands that prioritize ethical practices, we can contribute to a more sustainable fashion industry that values both style and environmental responsibility.”

In Conclusion

Lyocell fabric is playing a crucial role in the move towards a more eco-friendly and socially responsible fashion industry. It has gained recognition as an environmentally friendly fabric in sustainable fashion circles, and rightfully so. When we opt for lyocell and other sustainable fabrics when making purchases, we are helping to create a demand for clothing that is truly ethical.

The production process of lyocell fabric highlights its dedication to sustainability. Through a closed-loop system that reduces waste and resource usage, lyocell production sets an example for other manufacturing methods. The use of eco-friendly solvents and low-toxicity chemicals further minimizes its impact on the environment compared to traditional fabrics.

Additionally, lyocell offers several advantages that make it appealing to both conscious consumers and designers:

- Superior comfort, durability, and functionality

- Versatility for use in fashion and home furnishings

- Moisture-wicking and breathability for enhanced wearability

Looking ahead, there is potential for even greater sustainability in lyocell fabric production. Emerging technologies and innovations like recycling methods for post-consumer waste could further improve its environmental credentials. However, there are still challenges to overcome, and the industry is actively working on addressing them to ensure widespread adoption of sustainable practices.

In summary, choosing lyocell fabric is a positive step towards supporting a more sustainable fashion industry. By being mindful of our purchasing decisions and opting for eco-friendly materials, we can contribute to a greener future while enjoying the numerous benefits of this versatile fabric.

FAQs (Frequently Asked Questions)

What is lyocell fabric and why is it considered sustainable and eco-friendly?

Lyocell fabric is a type of rayon fabric known for its sustainable and eco-friendly properties. It is derived from wood pulp, and its production process involves the use of a closed-loop system to minimize waste and resource consumption. Additionally, eco-friendly solvents and low-toxicity chemicals are utilized in the production, resulting in a reduced environmental impact compared to other manufacturing methods.

How does the production process of lyocell fabric contribute to its sustainability?

The production process of lyocell fabric is considered sustainable due to the use of a closed-loop system, which helps minimize waste and resource consumption. Furthermore, eco-friendly solvents and low-toxicity chemicals are employed, ensuring a reduced environmental impact compared to other manufacturing methods.

What is the environmental footprint of lyocell fabric?

Lyocell fabric has a positive contribution to promoting sustainable forestry practices and mitigating the risk of intensive monoculture plantations. Its production process involves sustainable forestry practices, which sets it apart from conventional textiles like rayon and viscose. However, there may be potential areas for improvement in terms of its environmental profile.

What are the advantages and functional properties of lyocell fabric?

Lyocell fabric offers superior comfort, durability, moisture-wicking, and breathability, making it a preferred choice for both fashion and home applications. Its absorbent nature contributes to enhanced wearing experiences, further adding to its appeal.

What certifications and initiatives are important in ensuring the organic integrity of lyocell fabric?

Third-party certifications like GOTS (Global Organic Textile Standard) play a crucial role in ensuring the organic integrity of lyocell fabric, particularly when derived from sustainable sources such as eucalyptus trees. Additionally, organizations like Canopy drive sustainable practices within the lyocell industry, while forestry certifications such as PEFC and FSC also contribute to responsible sourcing.

In what industries can lyocell fabric be used?

Lyocell fabric has diverse applications across sectors such as clothing, home textiles, fashion, bed linens, and even technical textiles. Renowned brands and designers leverage its unique properties in their products across these industries.

What are some potential future innovations for enhancing the sustainability profile of lyocell fabric?

Emerging technologies or innovations could further enhance the sustainability profile of lyocell fabric. For example, recycling methods for post-consumer waste could be developed to support a more circular approach to production. However, there may still be barriers to widespread adoption that the industry needs to address.

Why should consumers consider choosing lyocell and other sustainable fabrics in their purchasing decisions?

Consumers should consider choosing lyocell and other sustainable fabrics to support the demand for truly ethical clothing. By opting for these materials, they contribute to the shift towards a more eco-friendly and socially responsible fashion industry.

Lyocell fabric properties Lyocell fabric uses Lyocell fabric production process Benefits of Lyocell fabric Lyocell vs. cotton fabric Sustainable Lyocell fabric Lyocell fabric care instructions Best brands for Lyocell fabric Durable Lyocell fabric Softness of Lyocell fabric Eco-friendly Lyocell fabric Lyocell fabric clothing Lyocell fabric bedding Lyocell fabric for sensitive skin

Lyocell fabric dyeing process